Development of the structure

One important constraint for us was the dimension of the foot of the sitski. Since it had to be compatible with standard ski bindings, it couldn't exceed ca. 330 mm in lenght and ca. 70 mm in width.

Starting from this, we made some sketches to have an idea of the shape and dimensions of the suspension system (both the suspension arm and the shock absorber). We developed an Excel file to compute the reaction forces, hence the force distribution, given the dimensions of the components. We noticed that mountain bike (downhill) dampers were the best solution for us: we also checked the stiffness parameters, that we found to be in agreement with the ones found in the competitors' products.

For what concerns the tilting, we took inspiration from the Piaggio MP3 three-wheeled motor-scooter, that features on the front axle a parallelogram. We adopted only this, since the suspension system was not suitable for us since it has no control over the pitching (the scooter has two footrests, we had only one!). With a Matlab script we determined the tilting angle needed to perform a turn, given the speed and the curve radius. We set the maximum tilting angle to 25 degrees from the horizontal, close to the angles reached by professional skiers in World Cup races (ca. 20 degrees).

Together with Roadrunnerfoot we chose Aluminium 7075 as the material, since it is light but very resistant (Yeld Strenght approx. 500 MPa). For less stressed components we could use Aluminum 6065. The components will be mainly machined from the bulk.

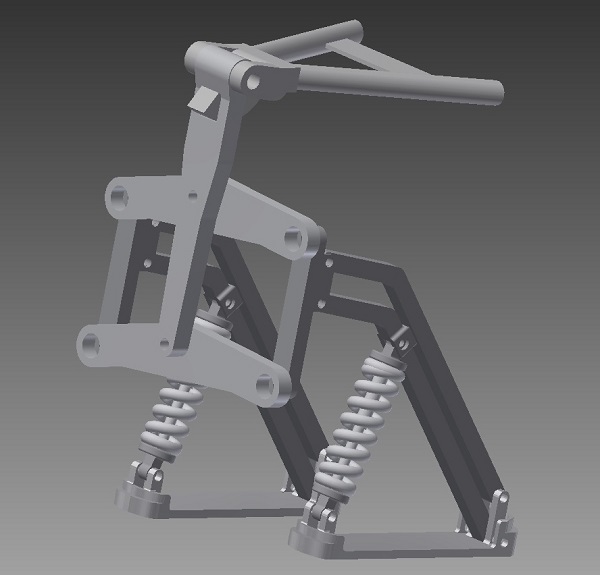

These considerations led us to the first shape for the assembly:

Problems and modifications

This first assembly wasn't only incomplete from the point of view of optimization of the single components: we had a huge "position" problem, since the center of mass was too much towards the "back".This resulted in a moment of forces opposite to the one we intended the system to work with: in practice the springs were working as extension spring instead of compression!

This forced us to design new suspension arms, to move the seat towards the front. The modifications however weren't so huge, in fact we had to change completely only the rigid arms.

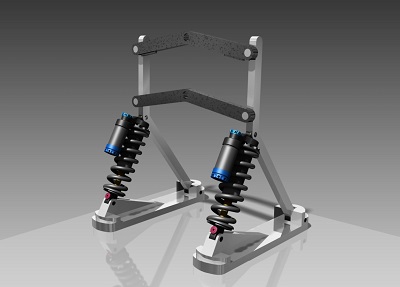

In addition to this, we achieved the total independence of the suspension installing a parallelogram on each leg of the frame. In this way we also cancelled the rotation of the seat: now it is just translating during the compression/extension of the shock absorbers. This is an advantage for the user, that can set once for all her/his best position and mantain it while skiing. Here you can see the upgraded system: