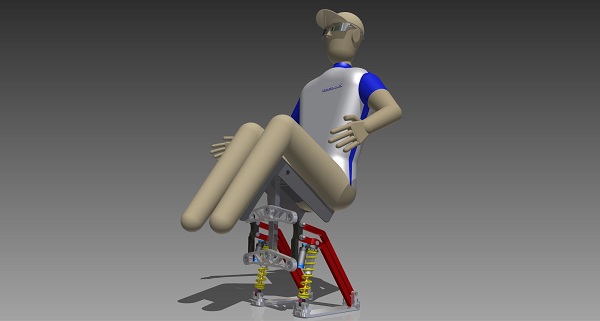

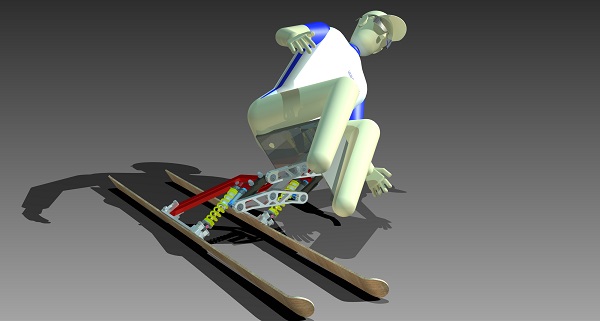

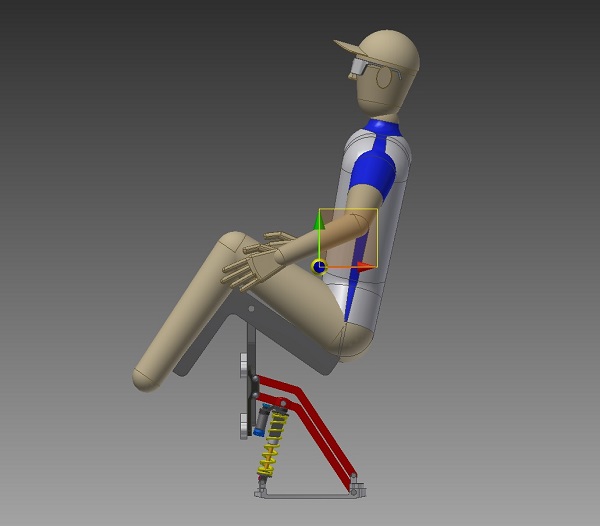

Final result

Once we completed every component, we built the overall assembly, including a basical sketch for the seat and the skis, and placing a mannequin. Since we worked completely within the Autodesk Inventor environment, which does not provide a mannequin, we downloaded a simple 3d model from here.

The system now weighs approx. 8,7 kilograms, without seat and skis. We consider this a good result.

We performed some dynamic simulations to see how the system behaved in different conditions. You can see some simple examples in the video below.

Seat raising mechanism

Since we didn't design the seat, we couldn't achieve a full engineering of the seat raisinh mechanism (to take the chairlift). We thought about an hinge, placed on the top of the underlying structure, where the seat is connected. We propose different solutions to block the seat rotation during the ride, and allow the raising of the seat:1- A fast-release pivot as in bicycle hubs, solid with the vertical part of the frame. The seat connection will have two open rings that will insert in the pivot and then blocked. PROs: cheap, easy to install, light, compact; CONs: has to be blocked before riding after the chairlift.

2- Two mobile wedges acted by springs mounted on the arc of the seat connection. If properly designed, the rider has to act on the system only once, as she/he prepares to seat on the chairlift.

Further improvements

We thought about some possible improvements to our system:- Full dynamic simulation with multibody dynamics software, to compute properly the forces acting on every single component;

- Design of the seat and implementation of ergonomic solutions;

- Customization of the system: the distance between the skis can be changed with a new design of just one geometry (the horizontal bar); it is also possible to think about multiple housings for the connection point of the different components, such that they can be slightly moved to meet the user's needs in term of riding height, vertical excursion, etc.;

- Proper engineering of the seat raising system;

- Use of composite materials instead of aluminum alloy where possible;

- Detailed cost analysis.

External links

For more information:

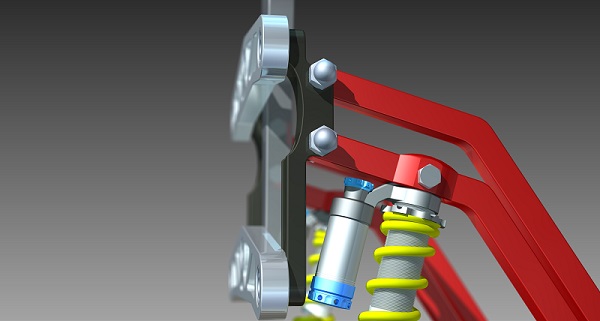

Detailed images

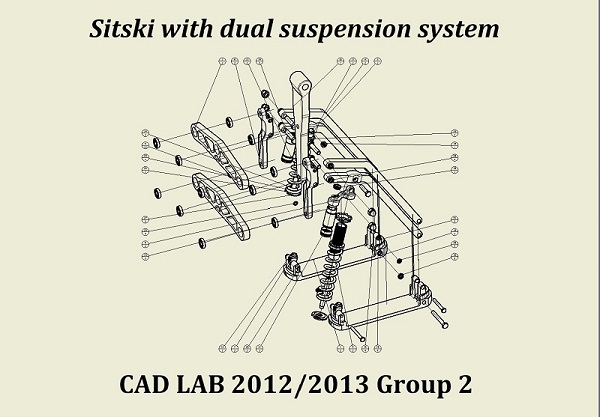

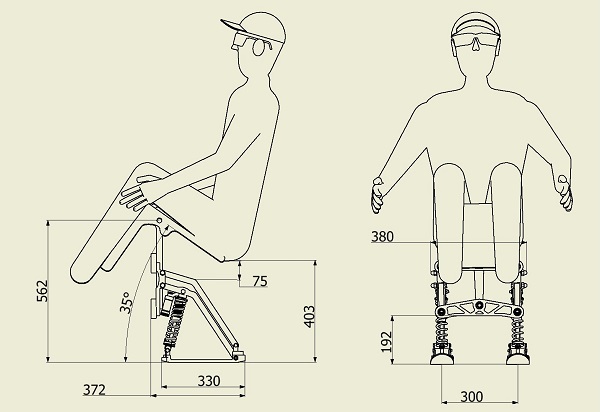

Here you can see an exploded view, the main dimensions and some other images