Description of the Project

Product development process includes several design and testing activities requiring engineers to review, modify and test several times a project before starting the manufacturing process. Aided-design tools (CAD systems) have been developed with the aim of assisting the designers, allowing them to control aspects like dimensioning, functionalities of products and their components. Reverse Engineering systems have been recently developed with the aim of reconstructing digital models of hand made objects, or of objects which are available only physically. CAD systems are used together with tools for the analysis, simulation, and quantitative evaluation of the characteristics and of the behavior of the designed products (CAE – Computer Aided Engineering systems). The design and analysis activities are today carried out through different modalities, tools and times, and also by different users. Because of that, time necessary for the products design/analysis phases are long, and may be definitely reduced by means of optimization and integration of tools and methodologies. Besides, still today, it often happens that reviewing phases are based on analyses performed on the basis of physical prototypes. Consequently, design time is long, and the total cost of projects increases.

Therefore, there is a growing interest in the development and use of digital methods and technologies which assist the product development process in an effective and efficient way, in a more and more competitive and complex industrial context.

Virtual Reality (VR) and Augmented Reality (AR) techniques and technologies have been successfully used for the development of some applications in the industrial sector and in the context of product development. Digital models of objects can be visualized in a realistic and immersive modality through stereo display (HMD – Head Mounted Display), data related to objects may be over-imposed onto the real context thanks to Augmented Reality visualization technologies (video see-through HMD), force-feedback haptic systems are used in order to modify the shape of a digital object in a realistic and intuitive way, by simulating the characteristics of shape and material, as they are perceived in reality.

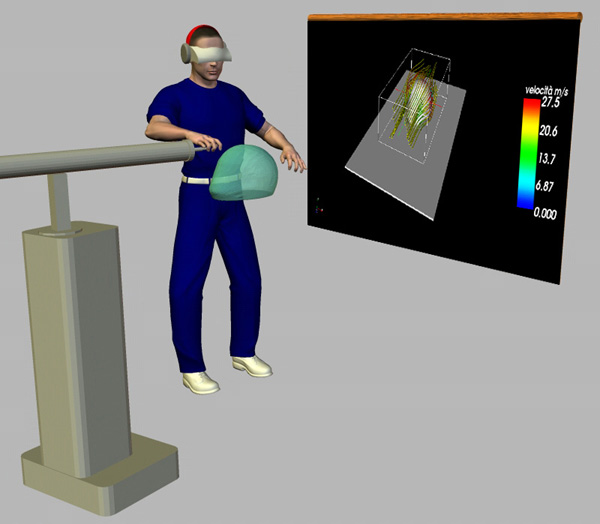

The objective of the research project is to use and validate the potentiality of these VR/AR technologies for improving and optimizing the design/analysis phase of a product. The project aims at studying and developing a virtual environment named PUODARSI (Product User-Oriented Development based on Augmented Reality and interactive Simulation) which allows designers to analyze, improve and optimize the performances of existing physical products in a contextual and direct way. The environment will allow users to reconstruct the digital model of a physical object by means of reverse engineering techniques, to display in an augmented reality environment, and to modify using haptic devices, the shape of an object, and to evaluate, in a contextual and comparative way, the effect that the modifications performed over the object shape may have on the structural and fluid-dynamics properties of the object. The environment will allow users to use and manage the modules, the documents and the history of the product, by integrating the various kinds of content related to the product. Figure 1 shows the concept of the PUODARSI system.

Figure 1 – Concept of the PUODARSI system.

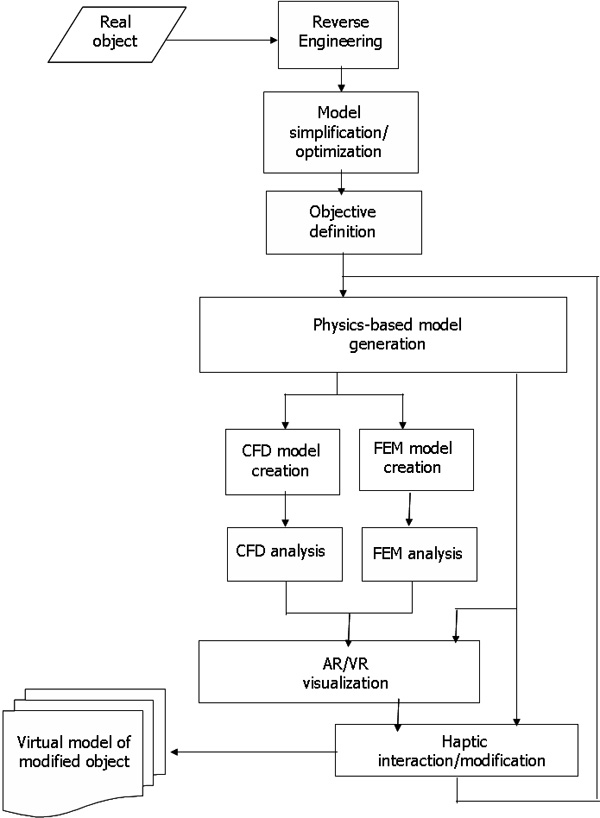

The new process we propose for the evaluation and optimization of the shape of an existing product is shown in Figure 2. The starting object is a physical product of which the CAD model is non existing or not accessible. The digital model of an object is reconstructed by means of the use of Reverse Engineering techniques. The geometric representation of the object is optimized and simplified in order to obtain a basic model which is appropriate for subsequent processing. Then, the user is required to state the objective of the analysis that is intended to perform in order to develop a physics-based model that can be used for the specific type of analysis, as well as for the modification performed using haptic devices. Then, the object model is represented as:

- a model made of contact surfaces to use for fluid-dynamic modeling and simulation (CFD);

- a model made by means of external patches to use for the stress analysis (FEM).

At this point, the system executes the requested analysis, of CFD or FEM type, and then displays the result in an augmented reality environment where the physical object and the analyzed virtual prototype are represented simultaneously, and within the same visualization space. The virtual environment is also equipped with haptic systems that allow the user to modify the shape of a virtual prototype, while feeling the physical characteristics of the object during the modification operations (material resistance, surface properties, objects mass, etc.).

In relation to the modifications performed on the object shape, the user can test again the model characteristics by means of the analysis environment, until the optimal shape is obtained. The system will be based on a distributed architecture, and it will be possible to use the modules in remote contexts, exploiting local computation resources. The modules may be used by various users, having profiles and different competences, in a collaborative way. The new proposed process and the PUODARSI system will be validated within the context of some text cases selected in the initial phase of the project. The effectiveness of the proposed approach will be tested and demonstrated in order to optimize the design/analysis phase, and to consequently reduce the performing times.

Figure 2 – Process for object shape optimization using the AR and haptic system PUODARSI.

Very innovative aspect of the project is the development of an environment of augmented reality where the user can modify the shape of an object by means of the use of haptic devices with the aim of optimizing it, and at the same time and in a comparative way of evaluating the performed modifications from a structural and fluid-dynamic point of view. All these will be available by using a unique system. This consists of a main improvement from the point of view of efficiency, times, and also system usability, in respect to techniques and tools currently available. The proposed approach is of particular significance for the industrial design context. In fact, the PUODARSI system aims to be a tool that allows the shortening of the total time devoted to product development mainly due to the fact that, for the easiness of use and usability features of the system interface, also designers will be able to evaluate and test -even if in a qualitative way– if the defined shape of the object satisfies some engineering constraints; this testing is typically performed at the end of the modeling activity, and usually produces numerous iterations of the shape modification/analysis tasks.

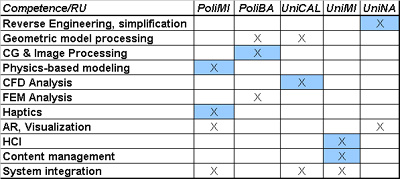

The research program is multi-disciplinary and the involved Units own complementary technologies and competences in the various research areas related to the research, so as to guarantee the achievements of the results. Table 1 shows the competences of the various research units in relation to the main research areas of the project. The unique competences of research units, not owned by other units, are highlighted in the table.

Table 1 – Competences of the Research Units.