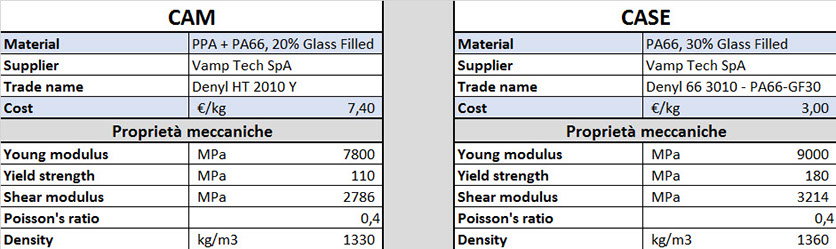

Materials and external parts to purchase

Considering informations received by Rold Group, it has been decided to use the same plastic materials of the current product, or similar anyway, for the realization of the new component. Moreover, we identified a possible supplier for these raw materials in Vamp Tech S.p.A, which also indicated to us some data about the specifications of these last:

It must be stated that these costs refer to an order of 1000kg, that is the minimum accepted.

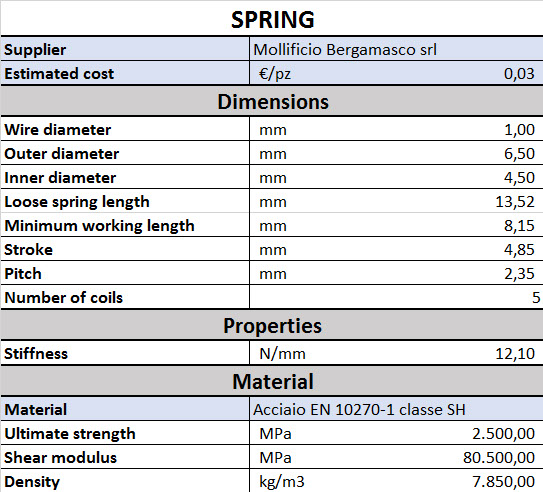

Regarding the spring, the only external component to be purchased, we chose a compression spring with the following specifications:

It has been dimensioned using the specific tool available in Autodesk Inventor.

According to the informations given us by the Rold representative, the spring would be custom-made. For this reason we supposed that the company can purchase from its present suppliers, such as Mollificio Bergamasco s.r.l.

In order to estimate the cost, we consulted some online catalogues and observed that for a similar component the price decreases considerably as the size of the order increases. After these considerations it seemed to us right to confirm a 0,03 €/u cost for orders of millions of units, as indicated by the company at the beginning.

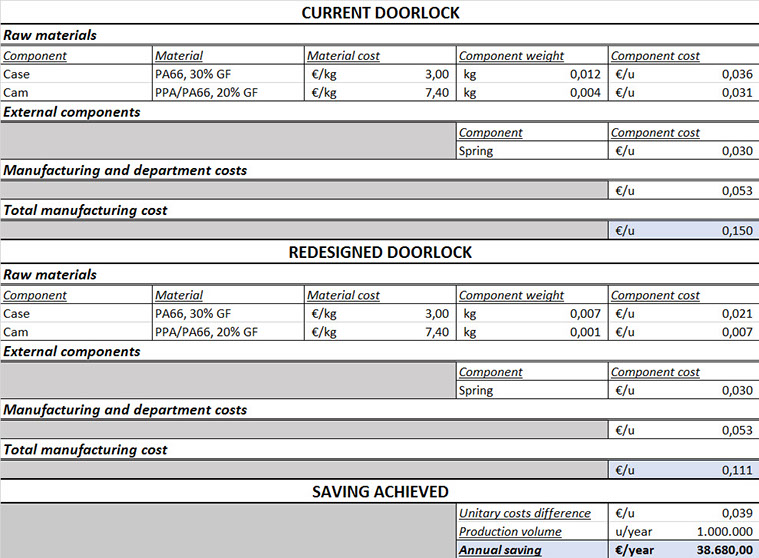

Costs estimate

With respect to the estimate of the total industrial cost of the product, we referred to an approximate value provided by Rold of 0,15 €/u for the current product (it has been discussed about a range of 0,10 – 0,20 €/u). Based on this figure, after having evaluated the raw materials expense for the current model, we got to estimate the manufacturing costs (molding, assembly) and other department/production costs affecting the product.

The table below provides details.

We supposed a manufacturing cost unchanged from the old to the new model, because the number of components and their maximum dimensions are the same or quite similar.

Having achieved a 0,04 €/u saving, we found the outcome of this estimate. This saving, evaluated on a supposed production volume of a million units, turns into an annual saving of about 40.000 €.

Besides, it must be observed that the cost could become even lower considering higher production volumes, of which the real data in unknown. In this way, in fact, it could be obtained a bulk discount for the plastics and the spring and a higher "diluition" of the department costs.

Laboratorio Progettuale CAD - Academic year 2015-2016